Plastic bags are practically everywhere and are a part of everyone’s daily life, but have you ever wondered “how are plastic bags made?” Most people are surprised to learn the highly technical and complicated process of making a plastic bag.

We believe in manufacturing quality products that signify the real art of packaging. we use the most excellent quality material to make the BOPP bags, PP/HDPE woven bag, and polyester pouch with the industry set standards and regulations. our bags are known for their perfect finish, long-lasting built, high quality, and lightweights. we are endorsed by a leading-edge infrastructure that's well equipped with the most modern machines and equipment.

Every year, approximately 1 trillion plastic bags are made — primarily because they are versatile and economical. Most importantly, plastic bags can be recycled over and over to create valuable post-consumer recycled (PCR) resins. Let’s take a closer look at how plastic bags are made as well as a cost-effective alternative to using virgin resins in plastic bag manufacturing.

Bag Manufacturing.

Plastic Bag Manufacturing Starts with Raw Material Extraction

- The first step of making plastic bags is to extract the raw material. This material — polyethylene —can be derived from either cracked natural gas or refined oil. Because these hydrocarbons are located below ground, they must be reached and extracted through the use of drilling wells.

The Refinery

- This refined oil or cracked natural gas is then transmitted to a refinery. When at the refinery, petroleum is separated into varying densities. This allows the oil that is required for the manufacturing of plastics to be extracted. The gas or oil is pressurized and superheated to make sure pure polyethylene chains are isolated. It’s vital to isolate these chains so they can be polymerized to form resin pellets of pure plastic.

- Varying amounts of pressure and heat will be used to manufacture resin pellets of different densities, which may be used for anything ranging from plastic shopping bags to grocery bags. For instance, grocery bags are commonly made of high-density polyethylene, which has a higher tensile strength than plastic films made from low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE).

- Plastic Film Extrusion

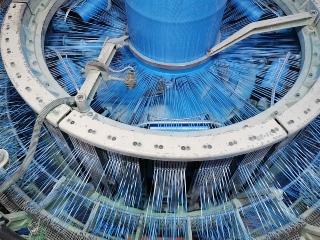

- Plastic film extrusion is the process of manufacturing raw pellets. It involves superheating and pressurizing raw LDPE, HDPE, or LLDPE plastic pellets to create a consistent molten liquid. Once the liquid is created, the resin is forced into a circular die. Then the hot resin is blown outward or upward to create a thin, long balloon of very pliable plastic film.

- The plastic bubble cools as it further expands, and it encounters several rollers that stretch it into very thin sheets, which will be the bag walls. The sheets are then rolled onto two individual flatbeds and moved into the printing machine.

Completing the Plastic Bag Manufacturing Process

- The last step starts with pressing the two printed sheets together to create the sides of the bag. The plastic can then be wound and cut to the most suitable size and shape based on the actual use or application for the bag. This is where additional customizations can be added, such as perforations.